R9100 super large preheating platform is suitable for the rework of surface mounting devices for 5G and other large servers. And this BGA rework station is suitable for the rework of 5G servers and large server mainboards.

As one of the top BGA Rework Station suppliers in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable product quality, full service. If you want to know some different types of BGA repair machines and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

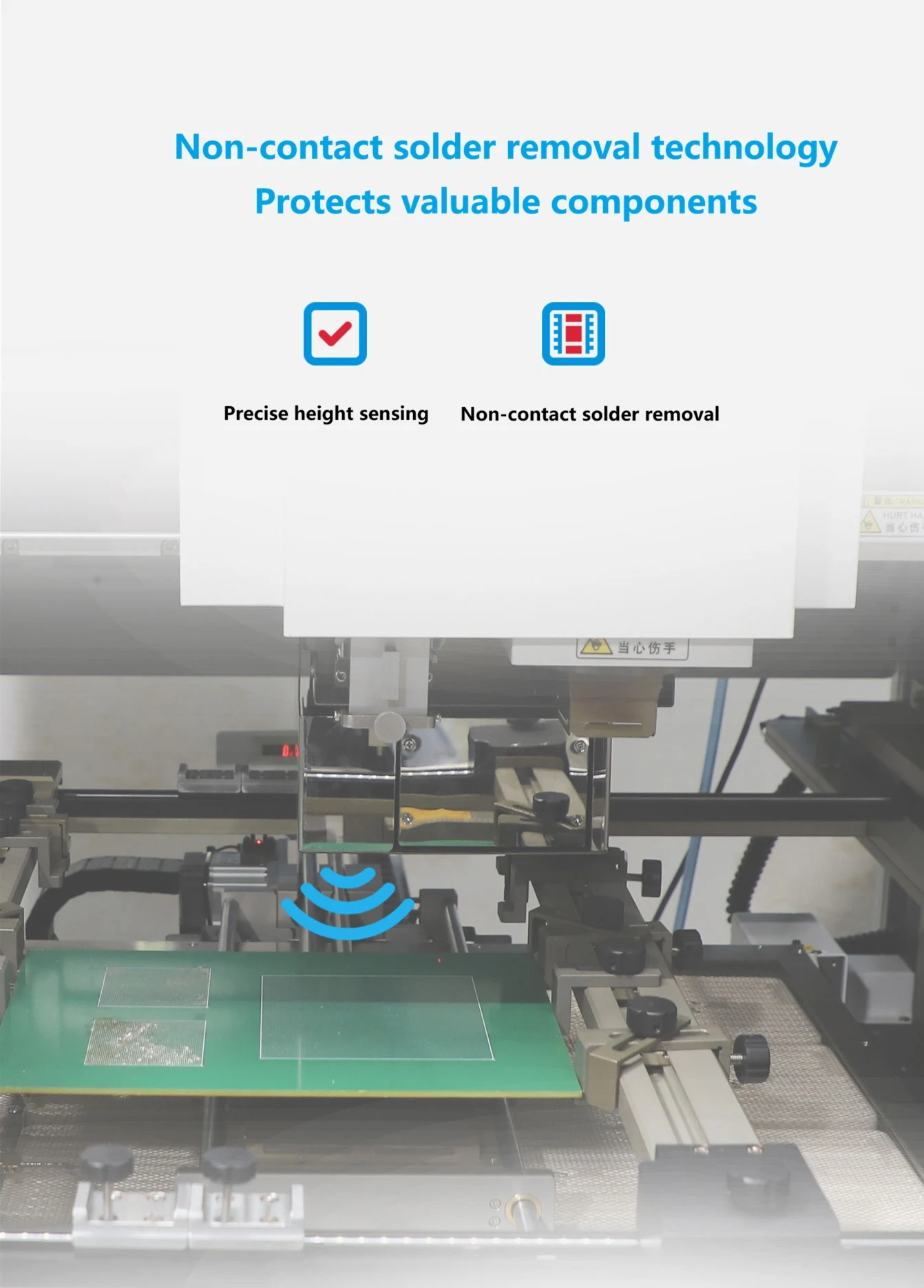

Non-contact desoldering is achieved with the assistance of precision load cells and barometric height measurement, reducing the risk of BGA damage, scrapping, and solder pad abrasion during the desoldering process. It also supports rapid generation of desoldering paths without Gerber files for panelized boards.

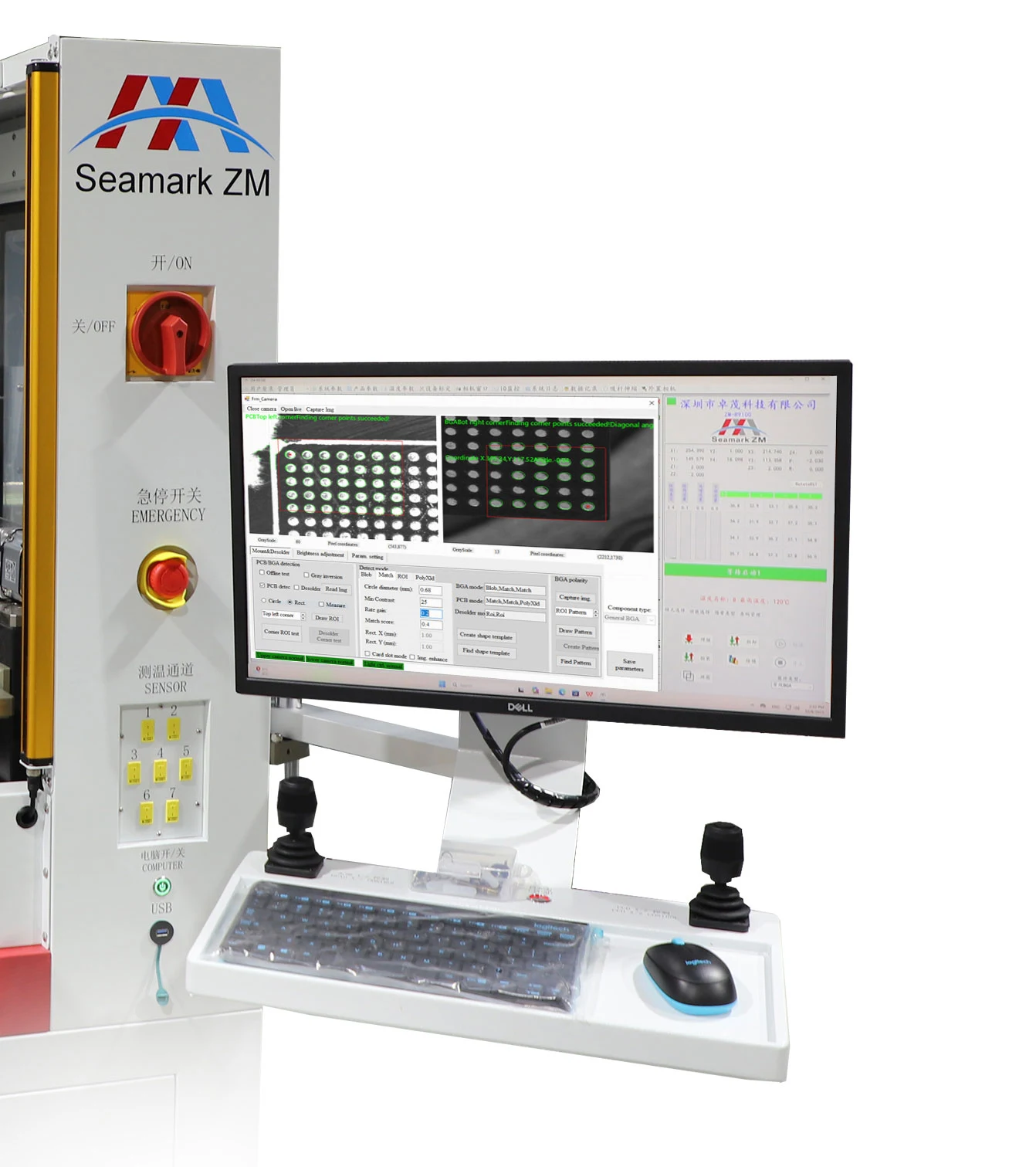

Equipped with a 5-megapixel top camera and a 12-megapixel bottom camera. Using independently developed control software and algorithms, the system delivers high alignment accuracy and a high level of automation. For rework at the same position on identical PCBs, alignment is required only once, after which “one-click rework” can be performed.

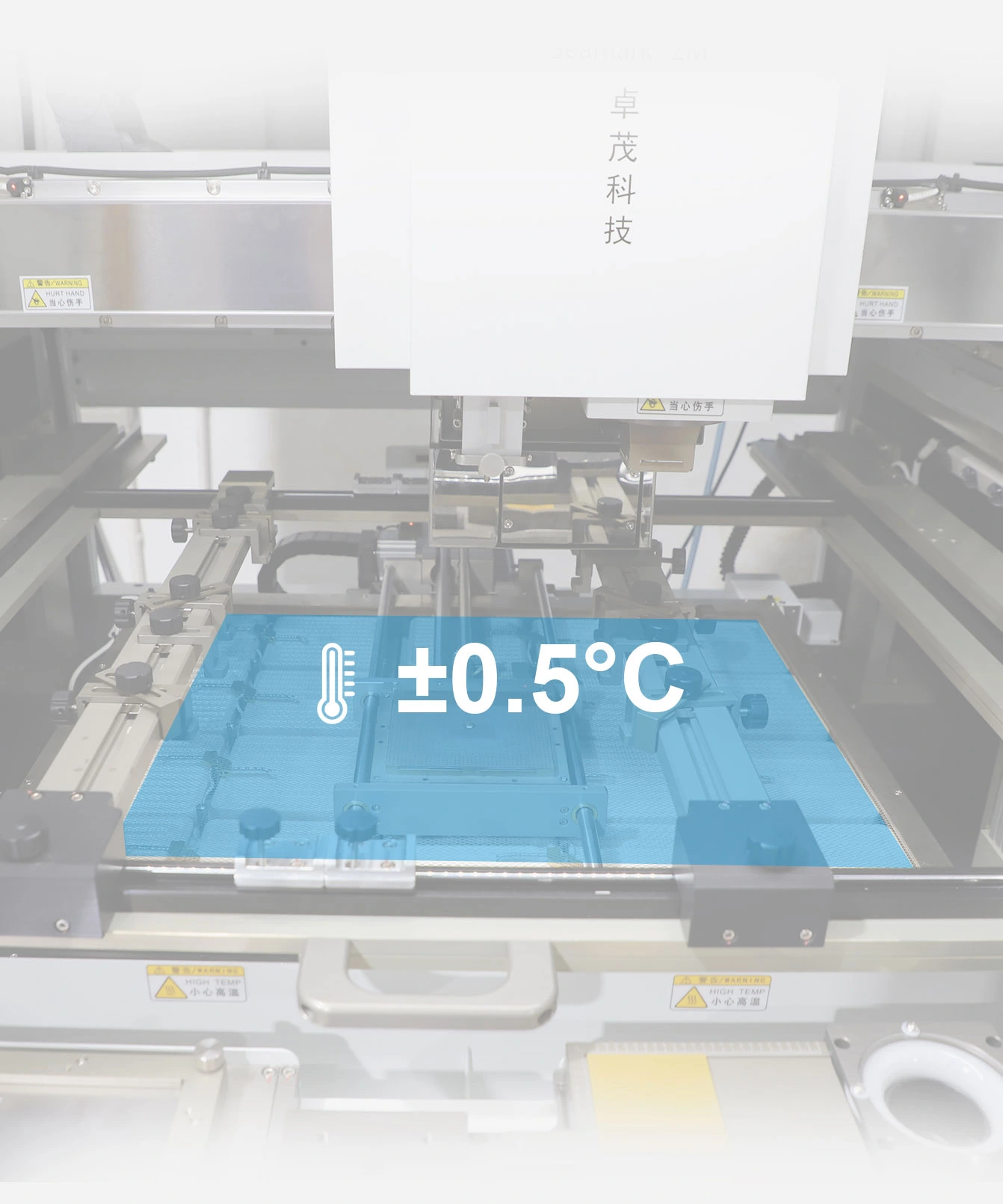

Configured with four independent preheating and heating platforms: top-side soldering/desoldering, top-side solder removal, bottom-side heating, and a movable temperature zone. Each platform is equipped with its own heating and temperature control system. All heating, preheating platforms, and the desoldering head adopt closed-loop temperature control, ensuring stable and accurate overall temperature regulation.

Strict standards are applied to product yield and operator safety. The equipment is equipped with dual-stage light curtains, independent secondary protection for each heating module, load cells on all downward-pressing modules, and limit switches on all doors and windows. Alarms are triggered in cases of over-temperature, personnel entering the working area, or position overtravel.

| Category | Model: ZM-R9100 | Specifications |

| Equipment Performance Parameters | Power | Total Power 22.8KW (Upper Temperature Zone: 2KW, Lower Temperature Zone: 2KW, Preheating Zone: 16KW, Desoldering Head: 1KW) |

| PCB Board Size | 700X635mm (Max) 10X10mm (Min) | |

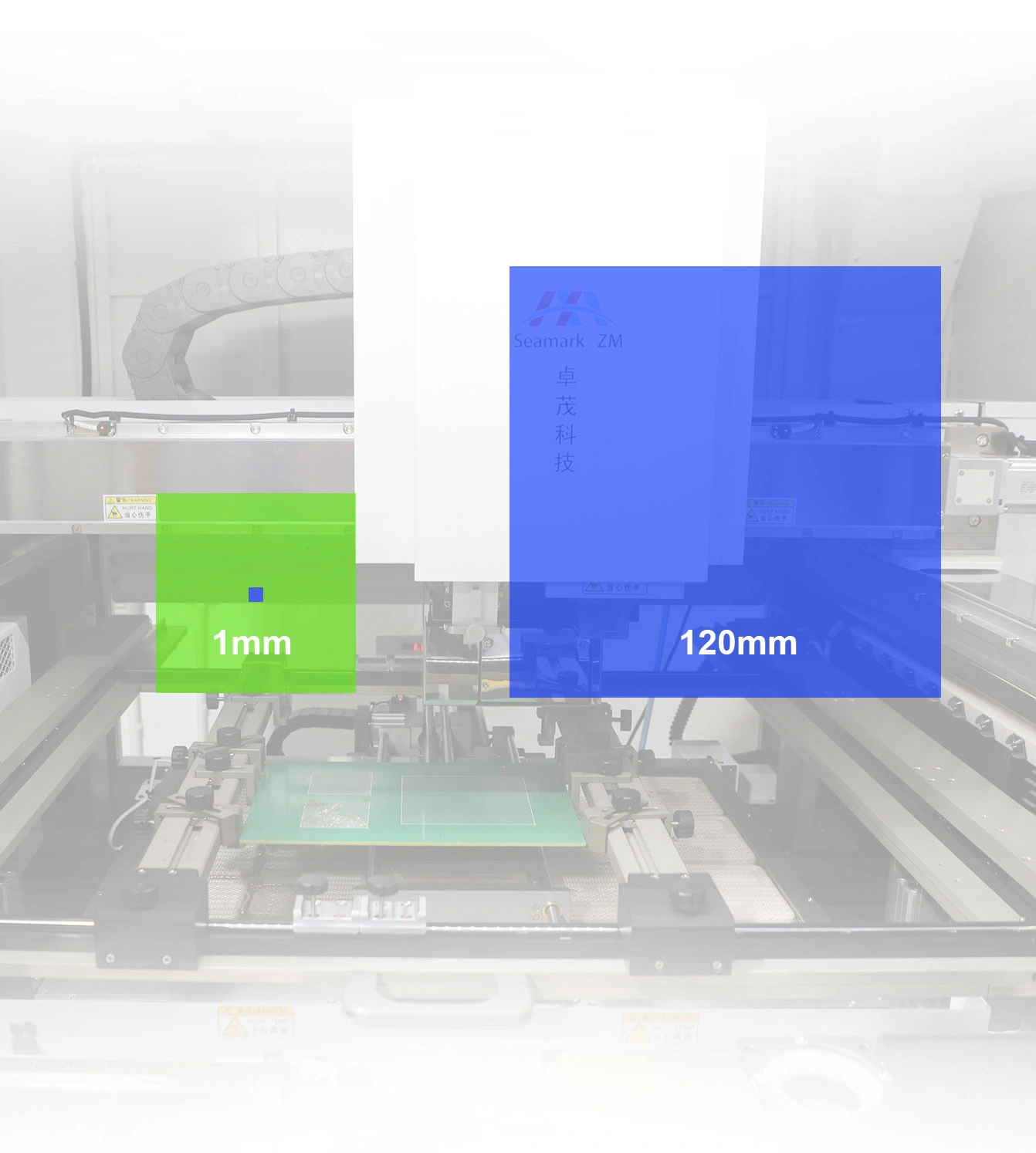

| Compatible Chip Size | 120mm*120mm (Max) 1mm*1mm (Min) | |

| IR Zone Size | 695mm*590mm | |

| Positioning Method | L-shaped Card Slot and Universal Fixture (Custom Special-shaped Fixture Available) | |

| Control System | Industrial PC + Servo Motion Control System | |

| Alignment Accuracy | ±0.025mm | |

| Desoldering Head Heater Temperature | ≤600°C (Adjustable) | |

| Desoldering Height Residue | ≤15% | |

| Desoldering Quantity Residue | ≤10% | |

| Desoldering Nozzle | Replaceable, Diameter Φ0.2mm-Φ3mm | |

| Desoldering Nozzle Height Control Method | Real-time Adjustment via Vacuum Feedback | |

| BGA Substrate Deformation | Flatness ≤0.15mm | |

| Solder Ball Size | 0.2mm-0.76mm | |

| Desoldering Recovery | Filter Cartridge Replacement | |

| Alignment System | Upper Camera: 5.0MP, Lower Camera: 12.0MP; Pixel Accuracy: 0.015mm/pixel, Field of View: Upper 39mm*29mm, Lower 59mm*44mm | |

| Product Changeover Time (After Debugging) | 20min | |

| Temperature Measurement Interface | 7 Interfaces | |

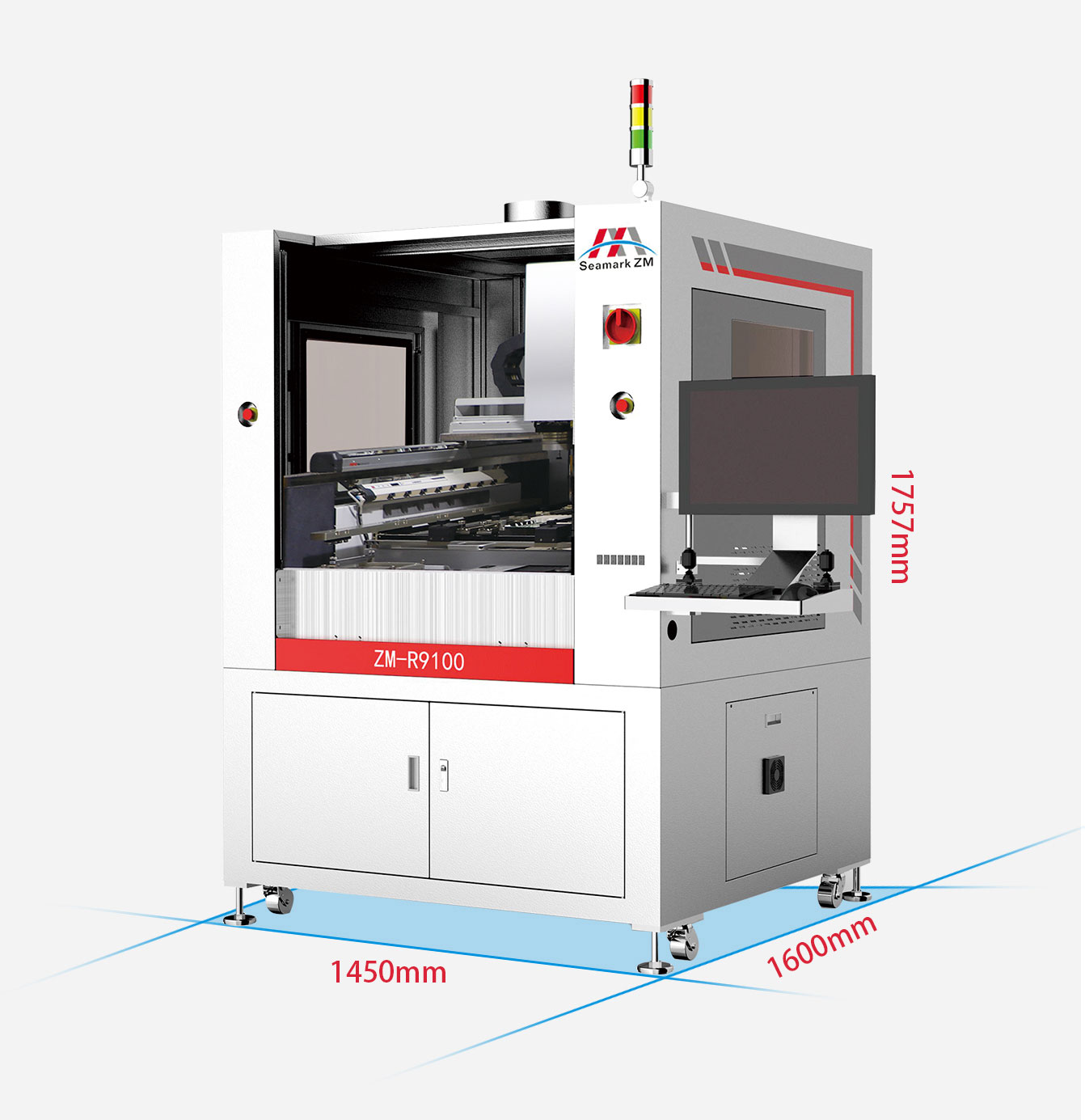

| Equipment Dimensions | L1450xW1600xH1757mm | |

| Equipment Weight | 1205KG |

The ZM-R9100 integrates multiple complex steps—disassembly, solder removal, solder dipping, component placement, and soldering—that previously required skilled technicians to perform manually, into a fully automated process. After completing the initial alignment, subsequent identical reworks can be performed with one-click operation, greatly reducing the operational threshold and dependence on skilled workers, and significantly improving rework efficiency.

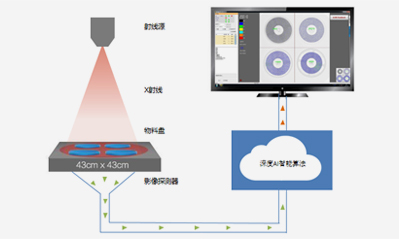

The equipment works through the coordination of a precision weighing sensor and a pneumatic height measurement system, accurately detecting the height to achieve non-contact solder removal between the desoldering tip and the pad, preventing mechanical scratches and significantly reducing the risk of BGA scrap and pad damage.

Seamark ZM R9100 is equipped with a 12-megapixel bottom camera and a 5-megapixel top camera, providing a pixel resolution of up to 0.015 mm/pixel, ensuring micrometer-level (±0.025 mm) alignment accuracy between components and pads, laying the foundation for high-quality rework.

The equipment is equipped with four independent heating zones, all featuring closed-loop temperature control. This design allows precise and independent control of the temperature profiles during preheating, heating, and soldering processes, ensuring uniform and stable heat transfer. It effectively prevents issues such as PCB warping, cold solder joints, or thermal damage caused by excessive temperature differences or thermal shock.

Zhuomao Technology R9100 rework station covers a rework range from 1 mm miniature chip components to large 120 mm BGA chips, and is capable of handling large PCBs up to 700 mm × 635 mm.

With interchangeable solder removal nozzles, it can flexibly meet rework requirements of different industries and specifications, including consumer electronics, communication equipment, and industrial control.

Equipment dimensions: L1450 × W1600 × H1757 mm.

It adopts an industrial PC combined with a servo motion control system, ensuring stable and precise execution of complex motion trajectories and logic control.

With a robust structure weighing 1205 kg, the system provides excellent stability and effectively suppresses vibration during operation.

It is a top-tier industrial-grade rework workstation, delivering outstanding performance in precision, intelligence, safety, efficiency, and reliability.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr