Invitation

Dear Customer,

Greetings! We sincerely appreciate your longstanding support for our company. On the occasion of the 32nd NEPCON China, we cordially invite you to visit our booth and look forward to your presence.

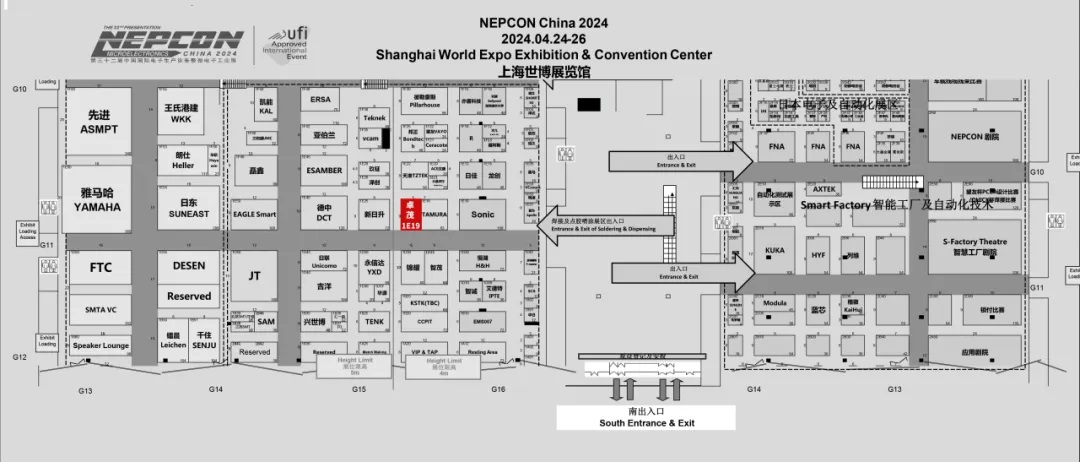

Date: April 24th to 26th, 2024

Add: Shanghai World Expo Exhibition & Convention Center

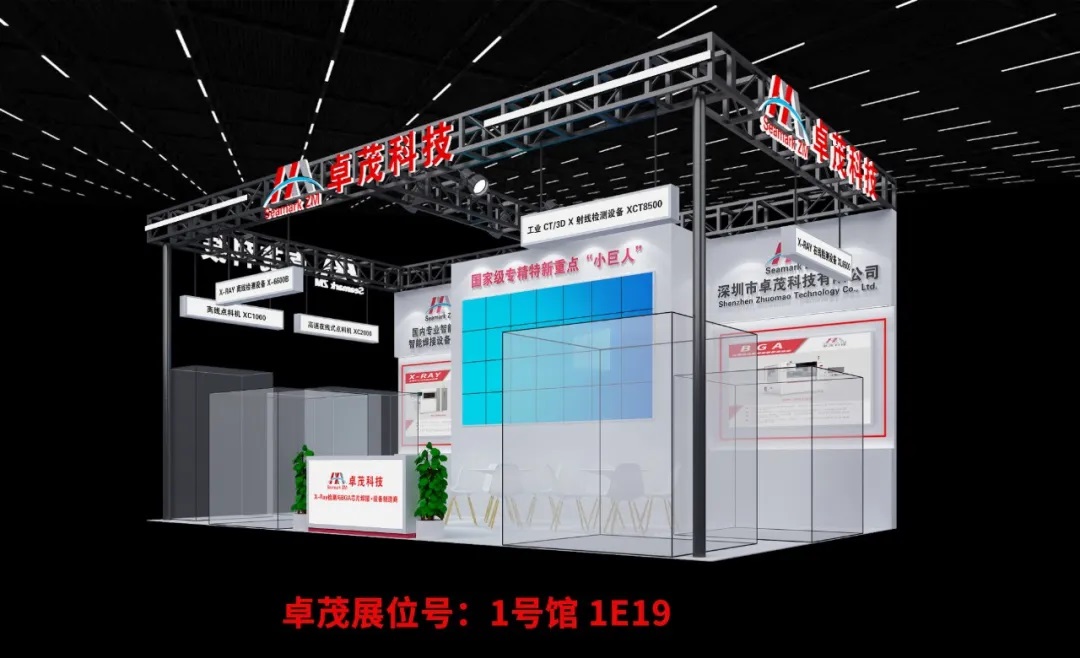

Booth Number: Hall 1, 1E19

Seamark ZM Technology Co., Ltd.

The 32nd NEPCON China, will take place from April 24th to 26th, 2024, at the Shanghai World Expo Exhibition & Convention Center. The exhibition will bring together high-end resources in the electronics manufacturing sector, featuring leading international brands across all categories of electronic manufacturing equipment, including printing, dispensing, mounting, curing, reflow soldering, cleaning, inspection, and repair equipment. Also, the upgraded IC Packaging Summit semiconductor packaging and testing summit will be held concurrently. The integration of the IoT exhibition with AIoT will present a panoramic view of surface mount technology!

About Us

SEAMARK is a national high-tech enterprise integrating research and development, production, and sales. It is designated as a national-level "Little Giant" enterprise focusing on intelligent inspection and welding equipment for 19 years. We specialize in providing advanced industrial CT/3D X-ray inspection equipment, X-Ray inspection equipment, X-Ray component placer, X-Ray lithium battery inspection equipment, intelligent BGA chip repair equipment, fully automatic die bonder, automatic desoldering equipment, and comprehensive solutions for industries such as electronic manufacturing, 5G communication boards, 3C products, lithium batteries, new energy vehicles, semiconductors, and industrial precision castings!

Exhibition Preview

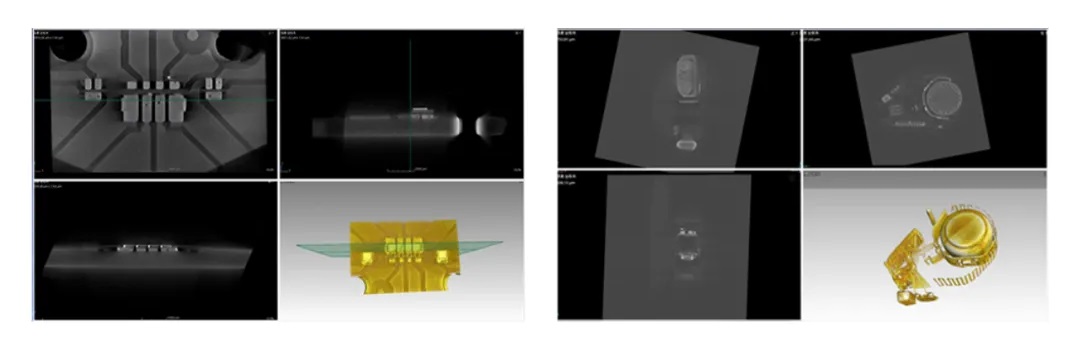

Industrial CT/3D X-ray Inspection Equipment XCT8500

Adopting an open-ray tube design, with defect detection capability reaching 0.5μm

Implementing 2D/3D/CT detection methods, suitable for quality testing, three-dimensional measurement, and non-destructive analysis

Equipped with plain CT function (PCT), applicable for 3D/CT testing of printed circuit boards, SMT, IGBT, wafers, sensors, aluminum castings, etc.

Left: Plain CT, layer analysis and measurement detection

Right: Cone beam CT, and 3D modeling

X-Ray Online Inspection Equipment XL6500

XL6500 Online Inspection Machine utilizes X-ray imaging for PCB board chip & IC soldering, missing components, empty soldering, BGA bubbles, and BGA soldering conditions. It is equipped with proprietary image algorithm software developed by SEAMARK, incorporating deep learning (AI) functionality for fast and automatic detection.

X-Ray Inspection Equipment X-6600B

Suitable for BGA chip inspection in electronic manufacturing and semiconductor industries

Rapid detection of bridging, voids, open circuits, solder quantity discrepancies, wire breaks, and hole alignment defects

High magnification, multi-angle inspection, and large-area inspection platform

High-speed Inline Automatic SMT Component Placer XC2000

High-speed inline automatic component placement in 8 seconds per tray for faster and more precise operation

Four-station rotary table for automatic feeding (with scanning), inspection, labeling, and unloading

Capable of high-speed component placement for various types of components

Offline SMT Component Placer XC1000

Innovative self-developed AI intelligent component placement algorithm software, capable of simultaneously counting 4 trays, rapidly and accurately accounting for material quantity, improving work efficiency, assisting SMT intelligent warehousing, and saving manpower.

Ergonomic design for convenient operation, featuring multiple safety protections; occupies small footprint, facilitating mobile operation.

Optical alignment automatic repair equipment ZM-R750

Independent control of three temperature zones, convection hot air heating, adjustable height of lower temperature zone, built-in vacuum suction tube in upper temperature zone for chip adsorption, equipped with negative pressure monitoring and pressure protection device; IR preheating temperature zone adopts carbon fiber infrared tube heating and high temperature-resistant microcrystalline panel protection, which can be moved left and right for easy maintenance of large and irregular PCBA.

Booth Guide

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru