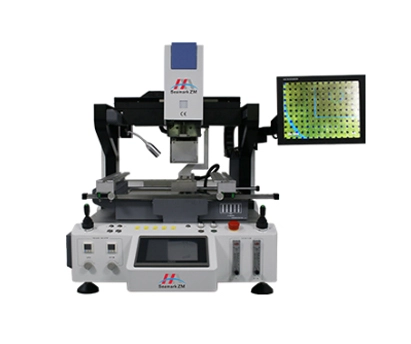

The BGA rework station, as the name suggests, is a machine used to rework BGA. BGA is a sealed chip. If there is a bad BGA on the production line, this machine needs to be used for rework. The BGA repair station for mobile adopts an integrated design of BGA device removal, placement, alignment, and soldering. It is suitable for the repair of BGA, CSP, POP, PTH, WLESP, QFN, CHIP0201/01005, shielding frames, modules, and other components on PCBA substrates such as servers, PC motherboards, tablet computers, and smart terminals.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru