Equipped with a feeder as standard to realize automatic feeding, automatic receivingfor small components, adding quick optical centering function, so that the suctionnozzle can quickly align the components and improve the repair efficiency.Equipped with a large-size infrared carbon fiber heater, the PCBA can be preheatedmore evenly. The hot air system adopts imported centrifugal fan, which has highuniform speed and high reliability.

Standard feeder equipped to realize automatic feeding.

Automatic receiving designed for small components

Equipped with fast optical alignment, enabling the nozzle to quickly align with components and improving rework efficiency

Equipped with a large-size infrared carbon fiber heater to ensure more uniform PCBA preheating

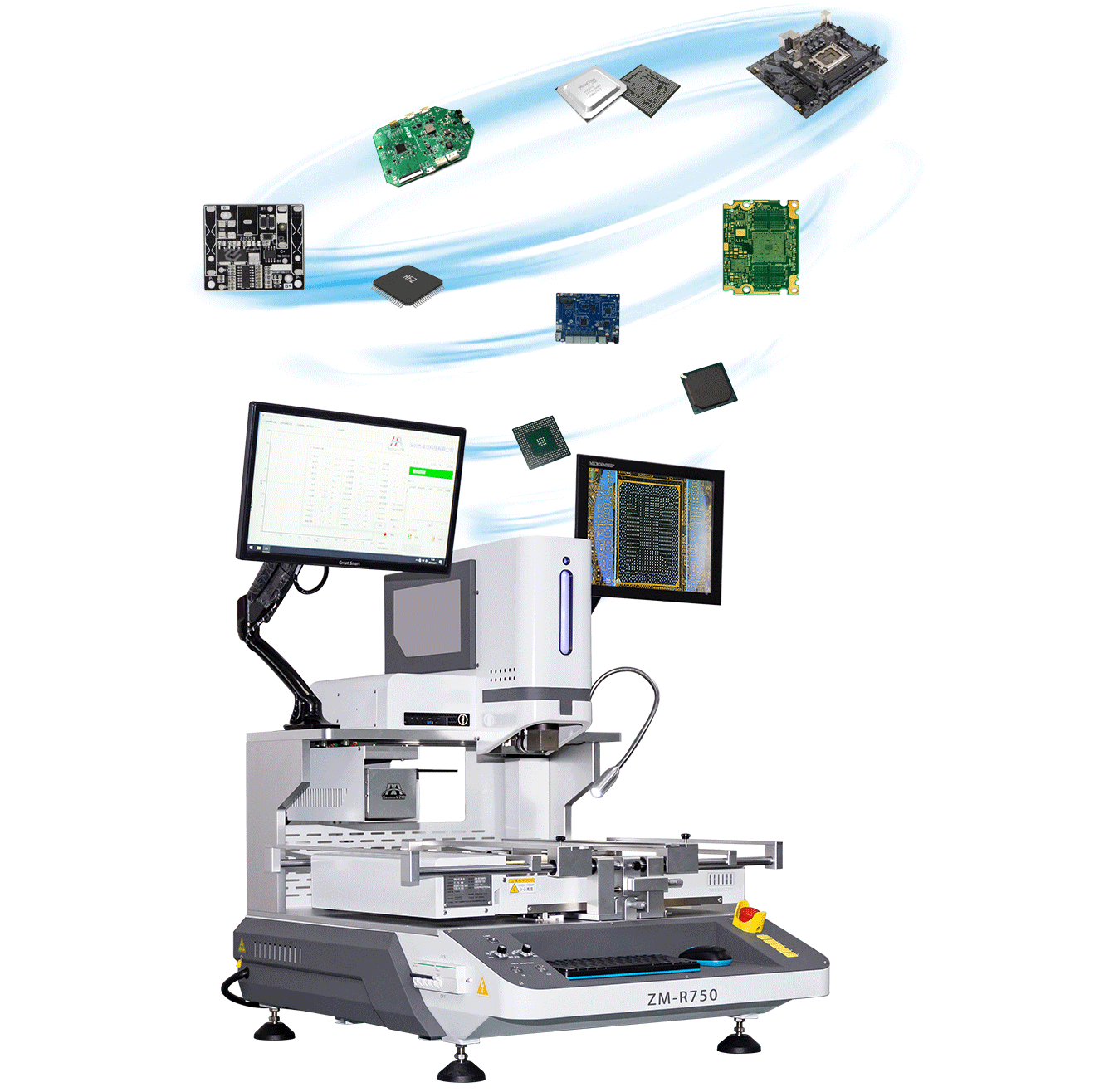

| Model No. | R750 |

| Power Supply | AC380V士10% 50/60Hz |

| Power | 7.75KW (Max) Top heafer (1.45 KW) Bottom heater (1.2 kw) IR Preheater(4.8 Kw) Others (0.3kw) |

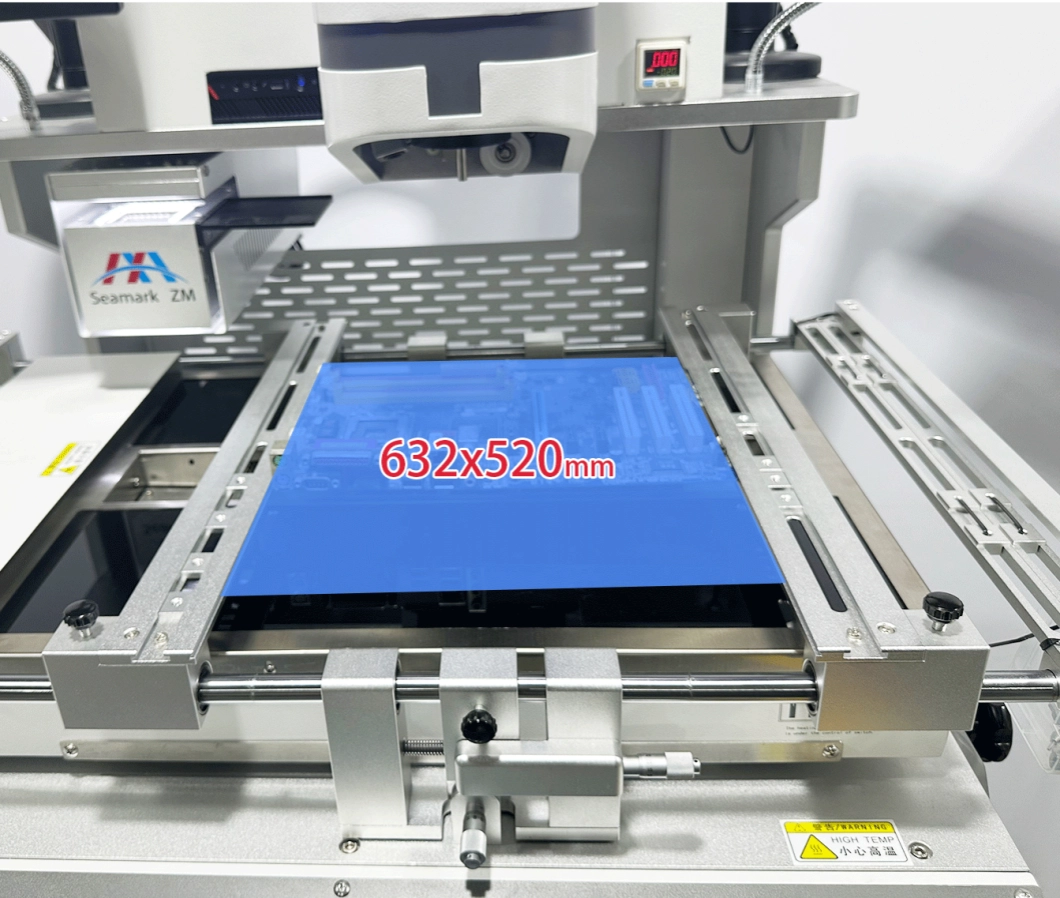

| PCB Size | 632x520mm(Max);6x6mm(Min) |

| BGA Chip Size | 80x80mm(Max):3x3mm(Min) |

| IR Temp. Zone Size | 570x435mm |

| Temp.Sensor | 5PCS |

| Vacuum Adsorption | Automatic |

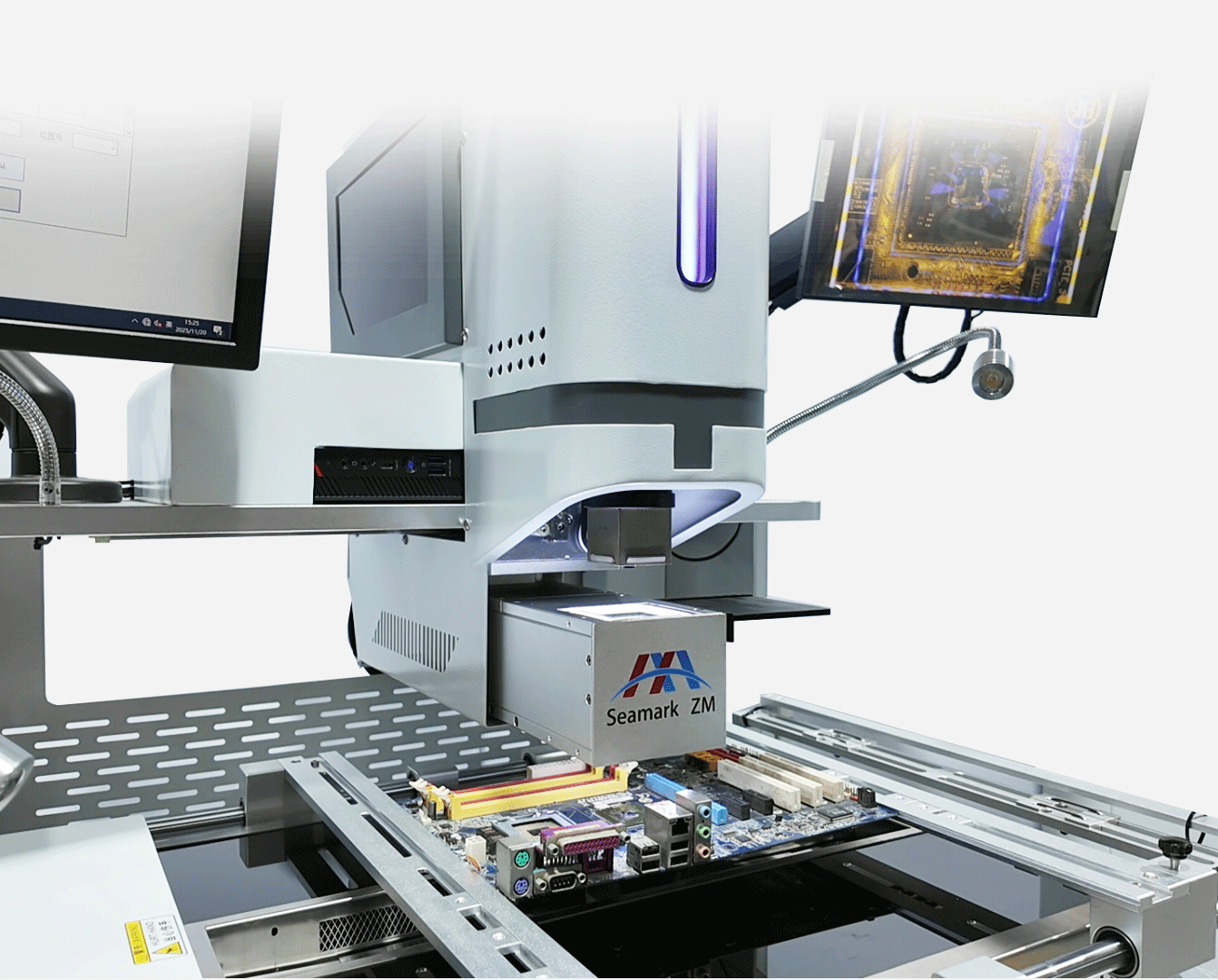

| Alignment System | 2m pixels HD digital imaging system, automaticopticalzoom with laser red-dot indicator |

| Contrtol System | Dell PC Main Unit + Motion Controller+ Temperature Control Module |

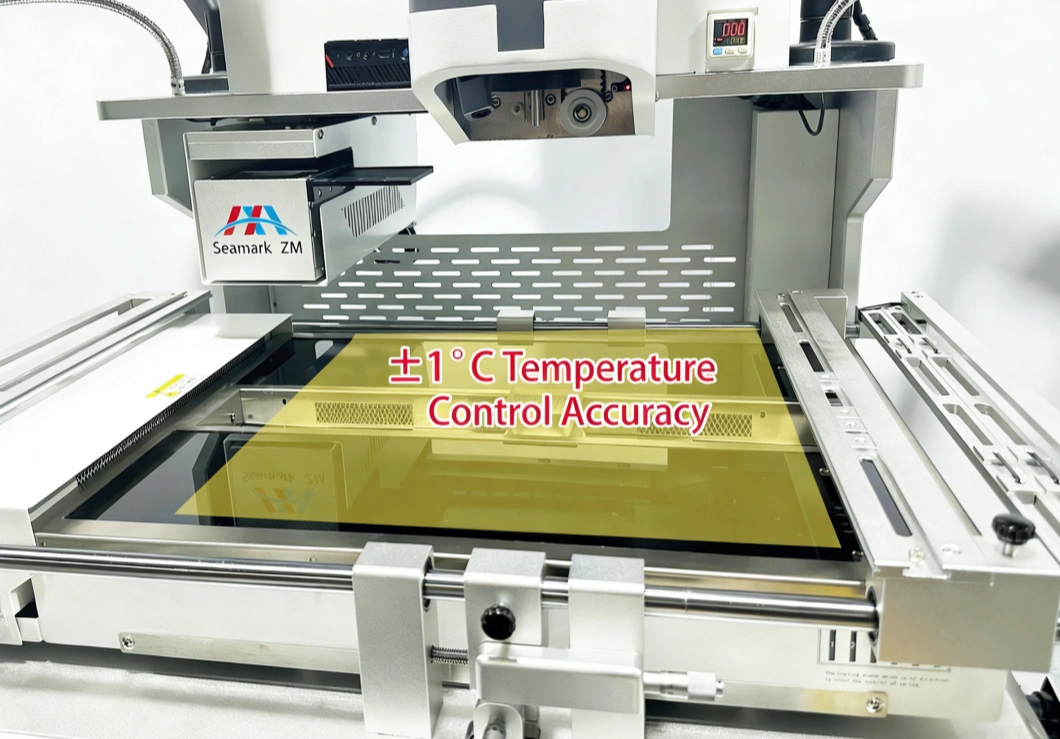

| Temp. Control | K-type thermocouple closed-loop controlwith accuracy up to +1°C |

| Alignment Accuravy | 士0.01mm |

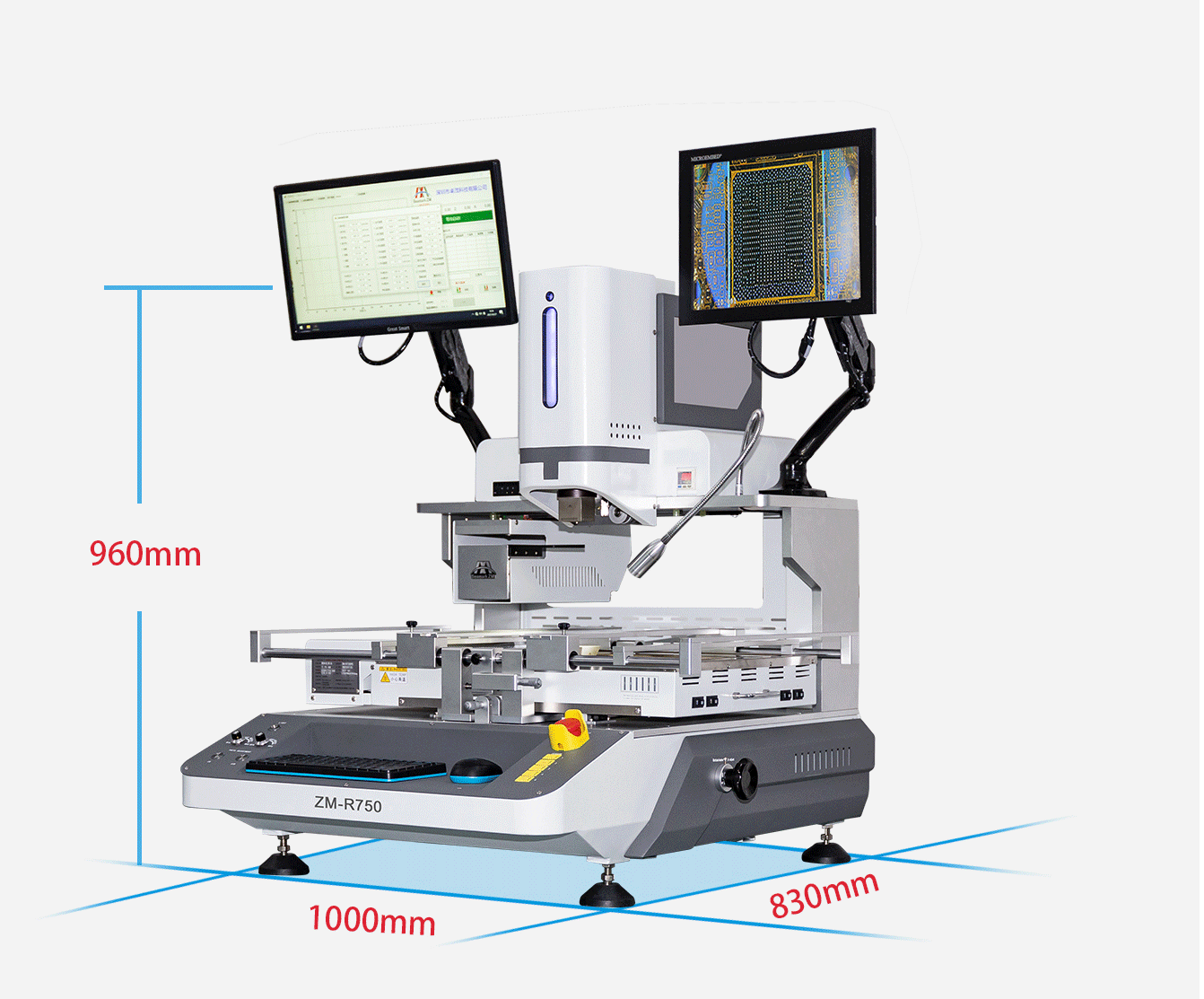

| Dimensions | L1000*W835*H960mm |

| Weight | 130.5KG |

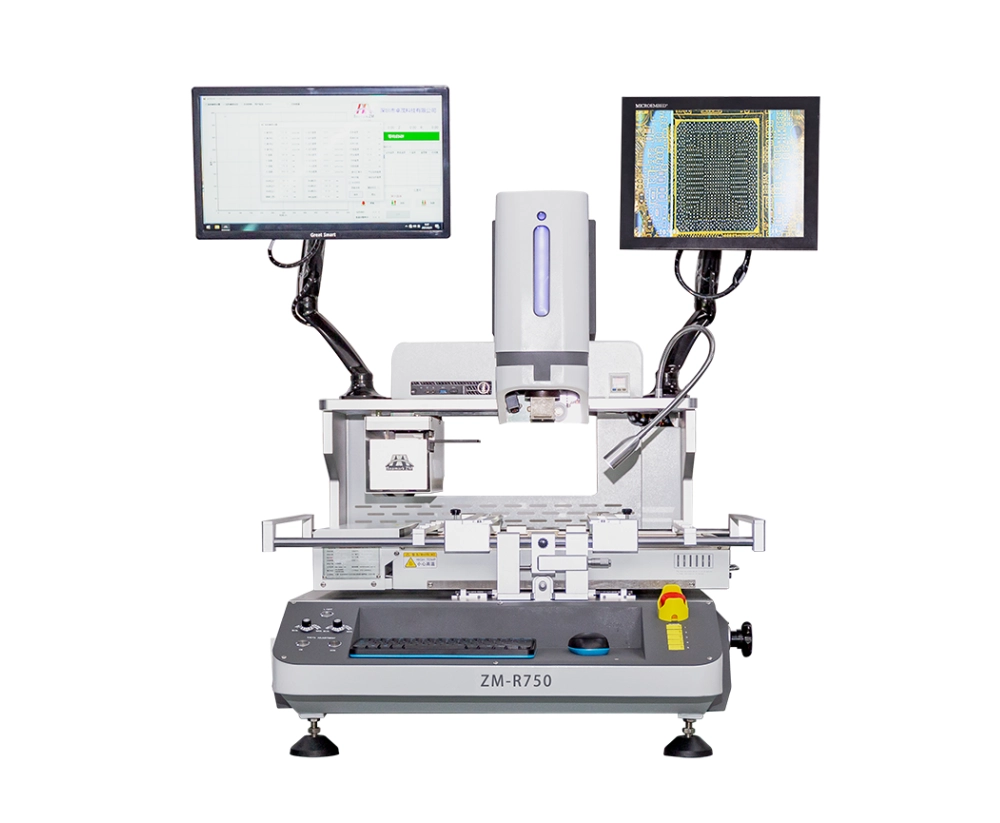

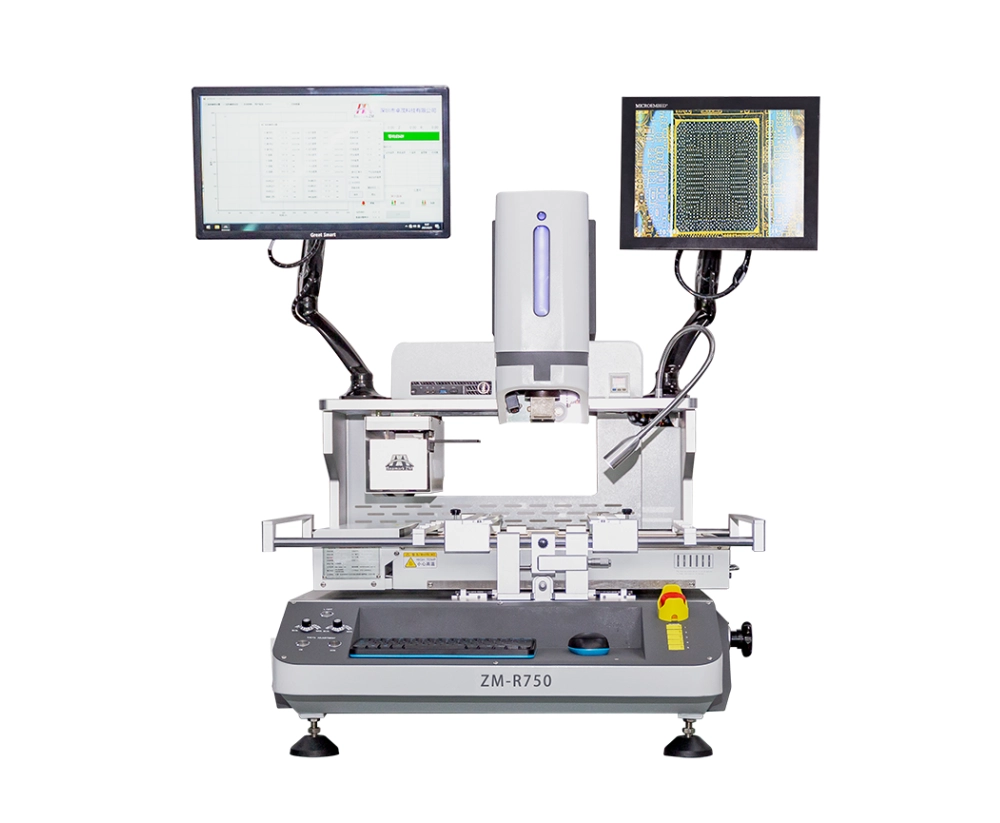

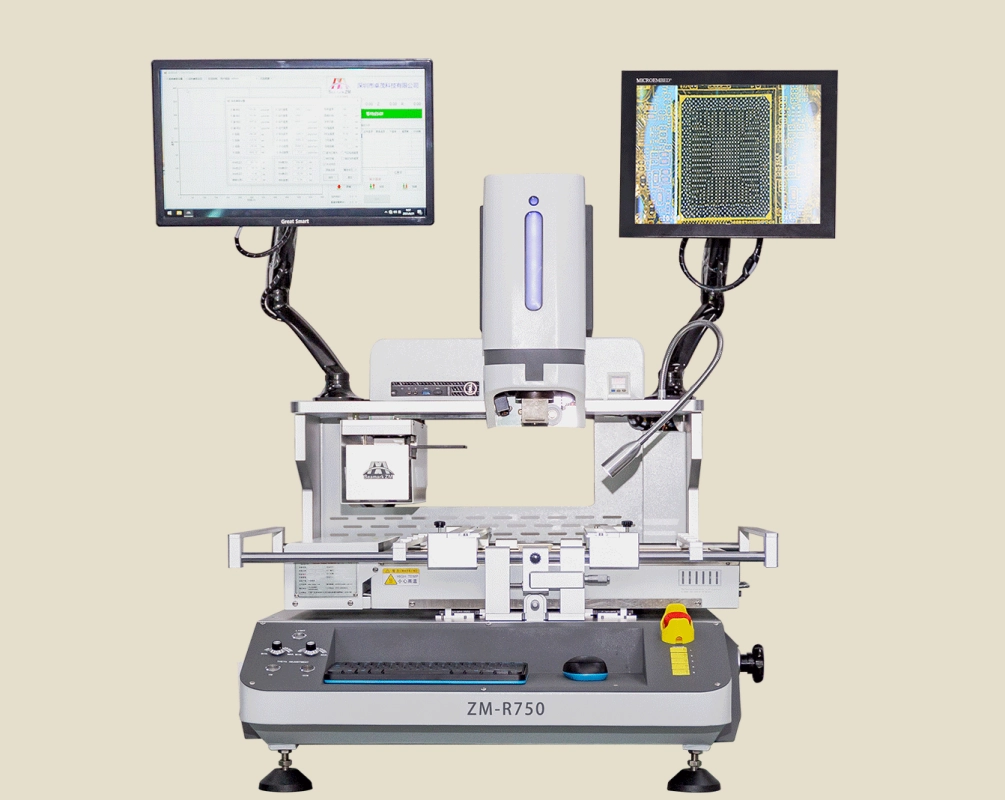

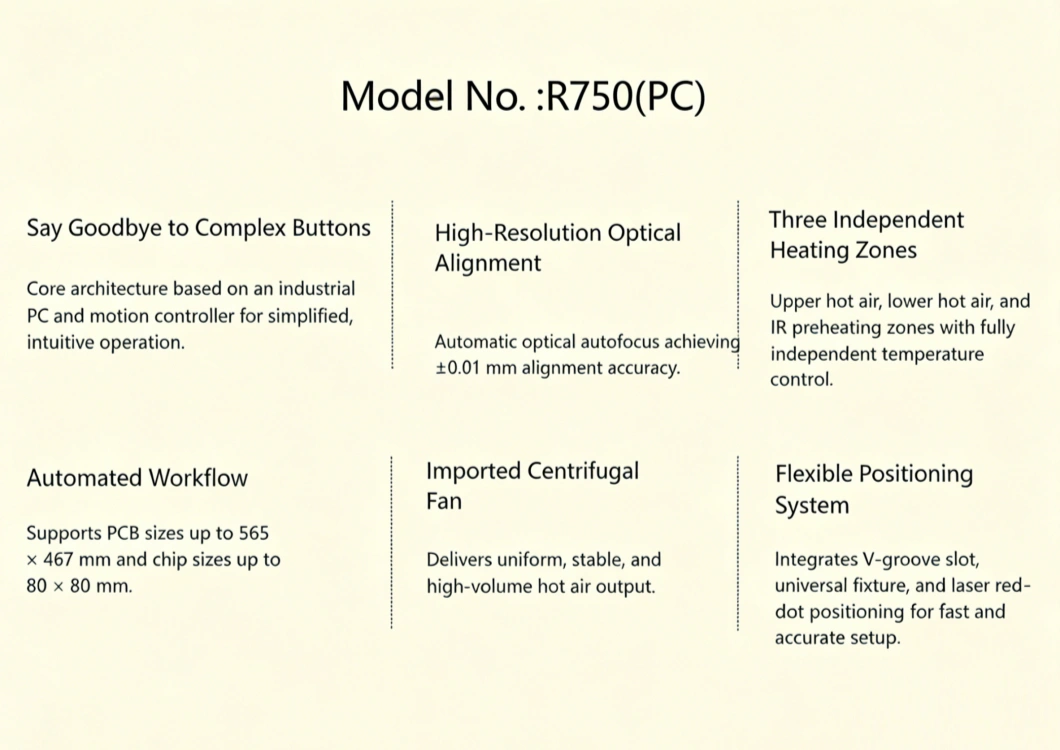

The ZM-R750 adopts an industrial PC combined with a motion controller as its core architecture, paired with a 19.5-inch high-definition display. Within the familiar Windows environment, operators can intuitively set, save, and recall unlimited rework process recipes through the software. This enables standardized and digitalized management of process parameters, providing a solid data foundation for quality traceability.

The system is equipped with a high-definition CCD optical alignment module, combined with automatic optical focusing, achieving ±0.01 mm alignment accuracy. This ensures that even the smallest solder joints can be precisely matched, providing “zero-error” assurance for the rework of valuable PCBs and high-end chips.

The ZM-R750 is equipped with three independent heating zones—top hot air, bottom hot air, and IR preheating—each capable of precise temperature control. The height-adjustable bottom heating zone optimizes hot-air transfer efficiency according to different PCB thicknesses, ensuring uniform heat penetration. From ultra-thin smartphone motherboards to thick industrial control boards, it delivers a fully customized thermal process solution.

The system delivers more than simple heating—it provides a complete, closed-loop selective reflow process. From alignment to thermal profiling, every stage is precisely monitored and continuously feedback-controlled, ensuring rework solder quality that closely matches the level of the original SMT production.

With its V-groove support and universal fixture for flexible positioning, the ZM-R750 can securely hold PCBs ranging from as small as 6×6 mm to as large as 632×520 mm. This wide size compatibility meets the rework requirements of nearly all boards on the production line and significantly improves asset utilization efficiency.

The system is equipped with an imported centrifugal blower, delivering uniform, stable, and high-volume hot airflow to form a consistent and precisely controlled temperature field within the heating zone. This ensures that components across every area of the PCB are soldered under identical thermal conditions, significantly improving rework process consistency and overall yield.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru