Trusted by Global Tier 1 EMS Providers like Celestica.

X6600 is a cost-effective general-purpose offline precision microfocus X-Ray inspection equipment. It is suitable for the inspection of various factory offline products. This AXI inspection machine has the characteristics of high magnification, multi-angle inspection, and a large-area inspection platform.

Meets general X-ray inspection requirements with broad applicability

Tilted multi-angle scanning makes it easier to detect sample defects

CNC inspection mode enables fast, automatic testing of multi-point arrays

Real-time radiation monitoring provides multiple layers of protection for operator safety

As a professional x-ray inspection machine manufacturer in China, Seamark ZM is famous for its rich technical force, complete detection means, reliable quality, good service. If you want to know the exact industrial x-ray machine price and to get a perfect kind of repair machine for your factory, please contact Seamark ZM first.

| X-Ray Tube Source Specification | |

| Type | Sealed Micro-Focus X-Ray Tube |

| Voltage | 90 KV/130KV |

| Operating Voltage Range | 40-90KV/130KV |

| Operating Current Range | 10-200 μA/300μA |

| Max Output Power | 8 W/39W |

| Micro Focus Spot Size | 5-15μm |

| Flat Panel Detector Specification | |

| Type | TFT Industrial Dynamic FPD |

| Pixel Matrix | 1536×1536 |

| Field of View | 130mm×130mm |

| Resolution | 5.8Lp/mm |

| Frame(1×1) | 20fps |

| A/D Conversion Bit | 16bits |

| Dimensions | L1360mm×W1240mm×H1700mm |

| Input Power | 220V 10A/110V 15A 50-60HZ |

| Max Sample Size | 540 mm×440mm |

| Control System | Industrial PC WIN7/ WIN10 64bits |

| Net Weight | Approx 1170KG |

| Radiation | <1μSv/h |

| Max Tilt Angle | 65 degree |

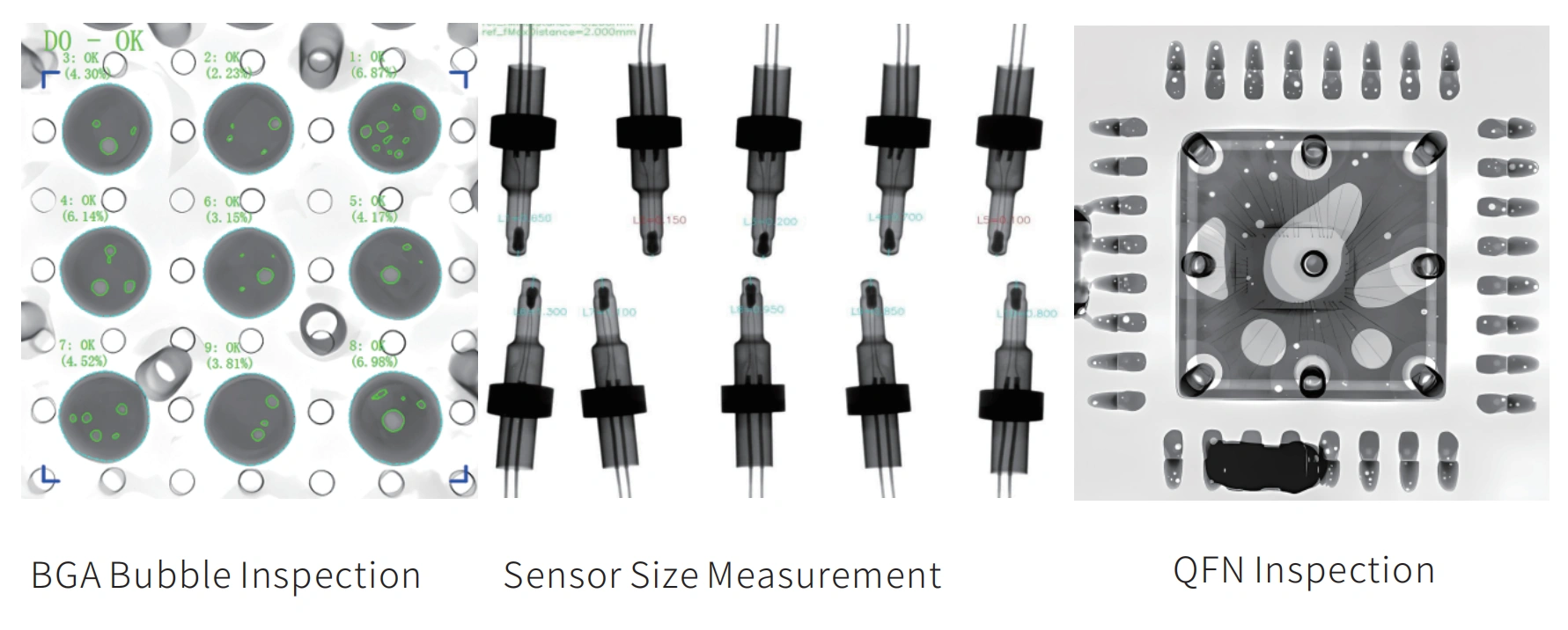

Automatic Defect Recognition

Can identify defects such as size, area, broken wire, bridging, etc.

Customizable Image Algorithm

Develop specific software algorithms based on customer product characteristics toachieve fully automatic defect recognition and Inspection functions, includingpresence, cracks, broken wires, offsets, size, quantity, etc.

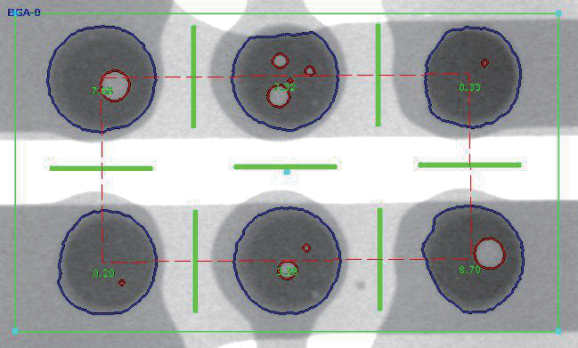

Enhanced BGA Extending Inspection Function

It can quickly select and mark a singlesoldering ball, or select the solderingballs to be inspected in a matrix, andcan manually or automatically identifythe BGA soldering balls and completethe inspection. Follow the systemguidelines to easily complete theinspection process and ensure accurateand reliable inspection results.

It can quickly select and mark a singlesoldering ball, or select the solderingballs to be inspected in a matrix, andcan manually or automatically identifythe BGA soldering balls and completethe inspection. Follow the systemguidelines to easily complete theinspection process and ensure accurateand reliable inspection results.

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru