Remote centralized review, barcode reading

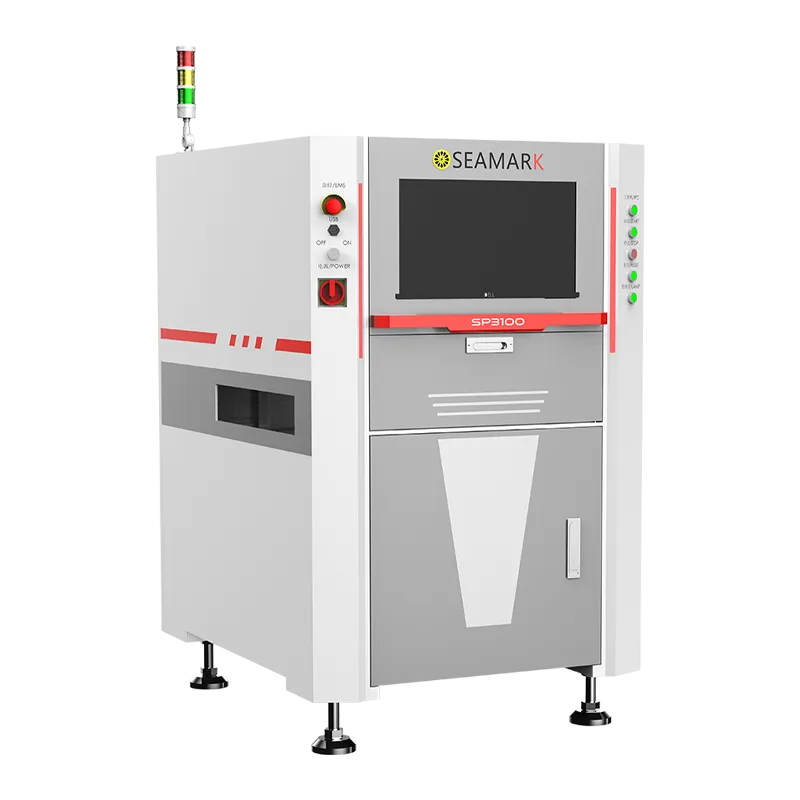

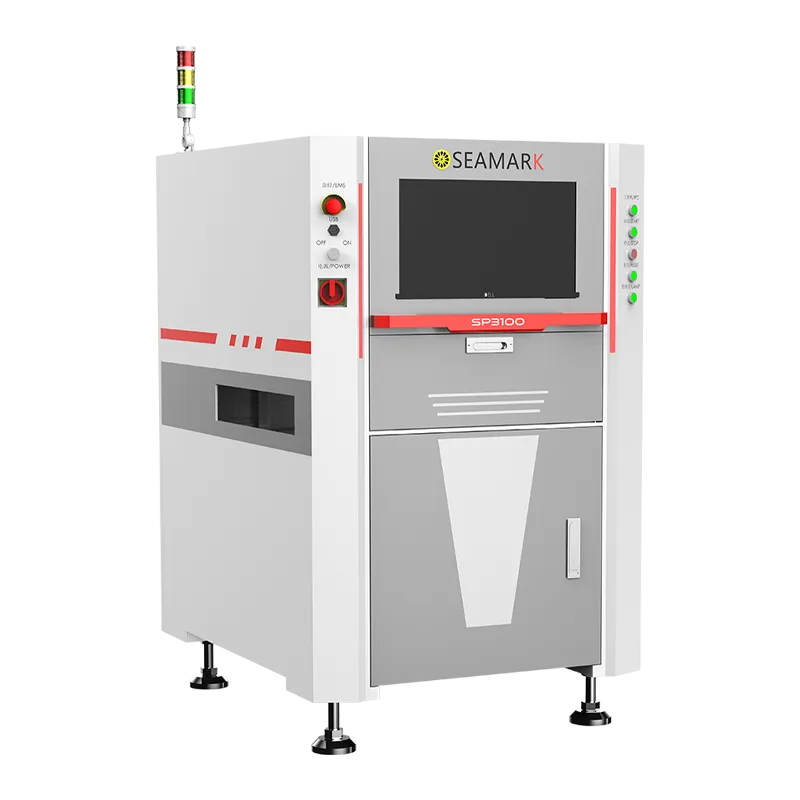

SP3100 is a pre-programmed SMT solder paste printing Automatic Optical Inspection (AOI) system. It is equipped with a multi-angle RGBW illumination system, dual low-angle projection modules, a high-resolution industrial camera with a telecentric lens, and a high-precision automatic Z-axis module.

The system scans solder paste on the PCB surface using combined 2D + 3D inspection. By applying phase-shift technology, it generates three-dimensional contour data, enabling accurate measurement of solder paste height, volume, and area with micron-level precision, even under complex process conditions.

SP3100 delivers high-accuracy 3D automated inspection and can effectively detect defects such as excess solder, insufficient solder, missing print, solder bridging, exposed copper, and positional offset.

High-precision 3D imaging technology with a dual low-angle projection system effectively minimizes shadowing and occlusion in fine-pitch components.

Equipped with a 12-megapixel high-resolution industrial camera (optional 21-megapixel), delivering high-clarity images to support high-speed inspection.

Supports integration with MES systems according to factory requirements.

Powerful SPC software provides comprehensive and precise statistical data analysis.

| Model | SP3100 | |

|---|---|---|

| Vision System | Imaging | 12MP industrial camera (21MP optional) |

| Resolution | 5μm/10μm/15μm | |

| Inspection Speed | 8.6c㎡/s 34.3c㎡/s 77.1c㎡/s | |

| Illumination | RGBW LED | |

| Hardware | Power Supply | 200V-230V AC 50/60Hz |

| Power Consumption | 2.2KW | |

| Air Pressure | 0.4-0.6MPa | |

| Weight | 1300KG | |

| Machine Dimensions | 1100mm(L)*1350mm(W)*1630mm(H) | |

| Inspection Specifications | PCB Size | 510*460mm |

| PCB Thickness | 0.4-6mm | |

| Edge Clearance | 3mm | |

| PCB Clearance (Top/Bottom) | 45mm | |

| Conveyor Height | 900±50mm | |

| Measurement Height | Components up to 2 mm in height | |

| Defect Detection | Excess solder, insufficient solder, missing print, bridging, exposed copper, offset, etc. | |

| Data Statistics & Analysis | Statistical Charts & Reports | Histogram, X-bar R/S charts, Cp/Cpk display, repeatability and reproducibility (R&R), daily/weekly/monthly/annual yield analysis |

| Optional Functions | Auxiliary Features | Remote centralized review, barcode reading |

EN

EN

es

es  ko

ko  de

de  it

it  pt

pt  th

th  ar

ar  pl

pl  vi

vi  tr

tr  ru

ru